info@cholifaucet.com

|

+86-13929086223 +86-750-2728690

As an excellent bathroom fitting manufacturing, our faucet is constructed from top-grade 59 copper, ensuring its durability and longevity. This material is not only pressure-proof and explosion-proof, but also highly resistant to any potential corrosion. This tap use one-button pull system, allowing you to effortlessly switch between two different water discharge modes. The main faucet ensures a soft and gentle water jet that won't splash and create unnecessary mess in your shower room. The handheld shower with a range of water discharge options. With the ability to choose from pulse, rainforest, or mixed water.

| Design Style | Modern, Contemporary |

| Laser Logo | Customized Logo (On Handle / Boby) |

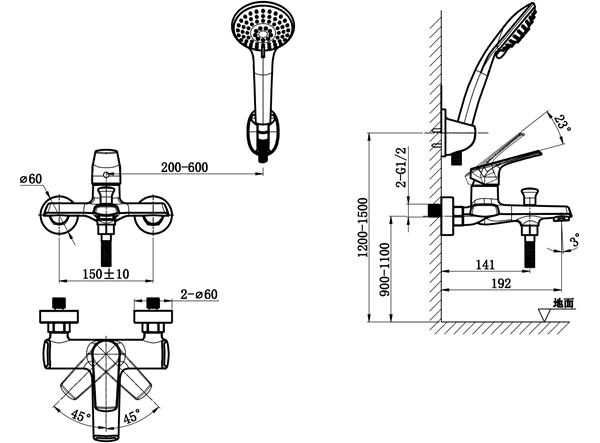

| Faucet Height | 192mm |

| Flow Rate | As aerator chooice |

| Aerator | As customers' requirements |

| Cartridge Material | As customers' requirements |

| Cartridge Lifetime | 500000 Times |

| Air Pressure testing | 0.6 Mpa |

| Water Pressure testing | 1.0 Mpa |

| Salt Spray Test | 24H Acid Salt Spray Test Based On Negotiation Grade |

1. Health and Safety Compliance:

Blast Proof Design: These taps are especially designed so that they may not ignite any flammable gas or vapour in dangerous areas. They meet strict safety requirements

2. Sturdy Build:

Tough Materials: Such faucets which can withstand the tough industrial environment are made from corrosion resistant high quality materials such as stainless steel or brass.

The materials used guarantee durability and dependability even under extreme condition.Hermetic Components: Its critical parts are hermetically sealed against dust, moisture, and gases; an essential requirement for maintaining its explosion-proof qualities.

3. Resistance to Corrosion and Chemicals:

Coating That Resist Decay: Most explosion-proof sink taps have a special coating that resists corrosion damage making them the right choice for places like chemical plants and refineries

where exposure to harsh substances is common.

4. Easy To Operate:

Ease of Use Designs: Despite being built to remain useful even when rough handlers mishandle them, these taps have been engineered in such a way that they do not require much effort while using them. It is also facilitated

by having handles that will fit well on palms of hands as well as smooth operation mechanism which enables one to control flow rate and temperature easily.

Touchless Options: In this event there are some models that operate without a touch through the use of infra red sensors in activating water flow. This has a safety and hygiene advantages of reducing physical contacts.

5. Versatility:

Various Configurations: Single and dual handles, wall mounted and deck mounted options are some of the many types of these sinks. Meaning that it can be installed in several applications as well as environments.

Adaptability: They can be used in various places including laboratories, petrochemical plants, pharmaceutical facilities where there may be explosive atmospheres.

6. Reliability and Maintenance:

Limited Servicing: Made to need less attention in terms of maintenance, such taps come with their own cleaning mechanisms plus strong seals that will cut down on how often they are serviced.

Long-Lasting: Through good manufacturing practices and vigorous testing explosion proof faucets have been designed for many years hence reduce downtime and maintenance costs.

7. Hygiene and Cleanliness:

Smoothness: Given that smooth surfaces can easily be cleaned they are necessary to maintain very high levels of hygiene such as those found in food processing companies or pharmaceutical production sites.

Antimicrobial Attributes: Additionally, certain blast-proof sink taps come with antimicrobial coatings to provide additional hygiene by inhibiting bacteria growth &

other microorganisms thereby improving sanitary conditions around the sink area.

8. Water Saving:

Reduced Water Flow: Some blast-proof sinks have an aerator attached to them so that they can save water while still being able to work properly because it lowers the rate of flow

without affecting its effectiveness thus resulting in water conservation which also saves money for you through low utility bills in due process.

Automatic Mode Off: Most touchless models also include an automatic shut-off feature that turns off the water after a preset period, providing further saving on wasted water

Chemical Plants And Refineries: They are essential in such places because they help ensure safety and corrosion resistance towards flammable gases and chemicals.

Pharmaceutical Facilities: Places where volatile substances are used and the need for safety and hygiene is paramount.

Laboratories: It provides safe water access in labs where hazardous materials are handled.

Oil And Gas Industries: Drilling platforms, processing plants and other places with explosive atmospheres.

Exploding-proof sink taps are required in hazardous environments for safety and functionality reasons considering the risks of explosion.

- Materials: High-quality, corrosion-resistant materials such as stainless steel and brass are typically used. These materials are chosen for their durability and resistance to harsh chemicals and environments.

- Certification: Yes, these taps are certified by recognized bodies to ensure they meet international safety standards.

- Installation: Installation should be performed by a qualified professional to ensure compliance with safety standards.

The process involves securely mounting the tap and connecting it to the water supply while ensuring that all components are sealed to prevent leaks and exposure to hazardous materials.

- Maintenance: Regular inspections and maintenance are required to ensure the taps remain in good working condition.

This includes checking for leaks, ensuring seals and gaskets are intact, and cleaning the surfaces to prevent buildup of corrosive substances.

- Touchless Operation**: Yes, some explosion-proof sink taps come with touchless operation features.

These use motion sensors to activate the water flow, which enhances hygiene and further reduces the risk of ignition by eliminating the need for manual operation.

- Benefits:

- Safety: They significantly reduce the risk of explosions in hazardous environments.

- Durability: Constructed from robust materials to withstand harsh conditions.

- Compliance: Meet international safety standards and certifications.

- Hygiene: Touchless models improve hygiene by minimizing contact.

- Corrosion Resistance: Suitable for environments with aggressive chemicals.

| Packaging & Delivery | |

| Packing | Cotton bag, bubble bag, sponge( As customers' requirements) |

| Business Term | FOB or EX-WORK |

| Terms of Payment | T/T |

| Peak Season Lead time | 3-4 Months |

| Off Season Lead time | 1-2 Months |

| Place of Origin | Guangdong,China |

| Service | |

| OEM and ODM | Both |

| After-sale Service | Online Technical Support |

| Project Solution Capability | Craphic Design, 3D Model Design |

| Warranty Service | 5 Years |

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now Youtube

Youtube